Description

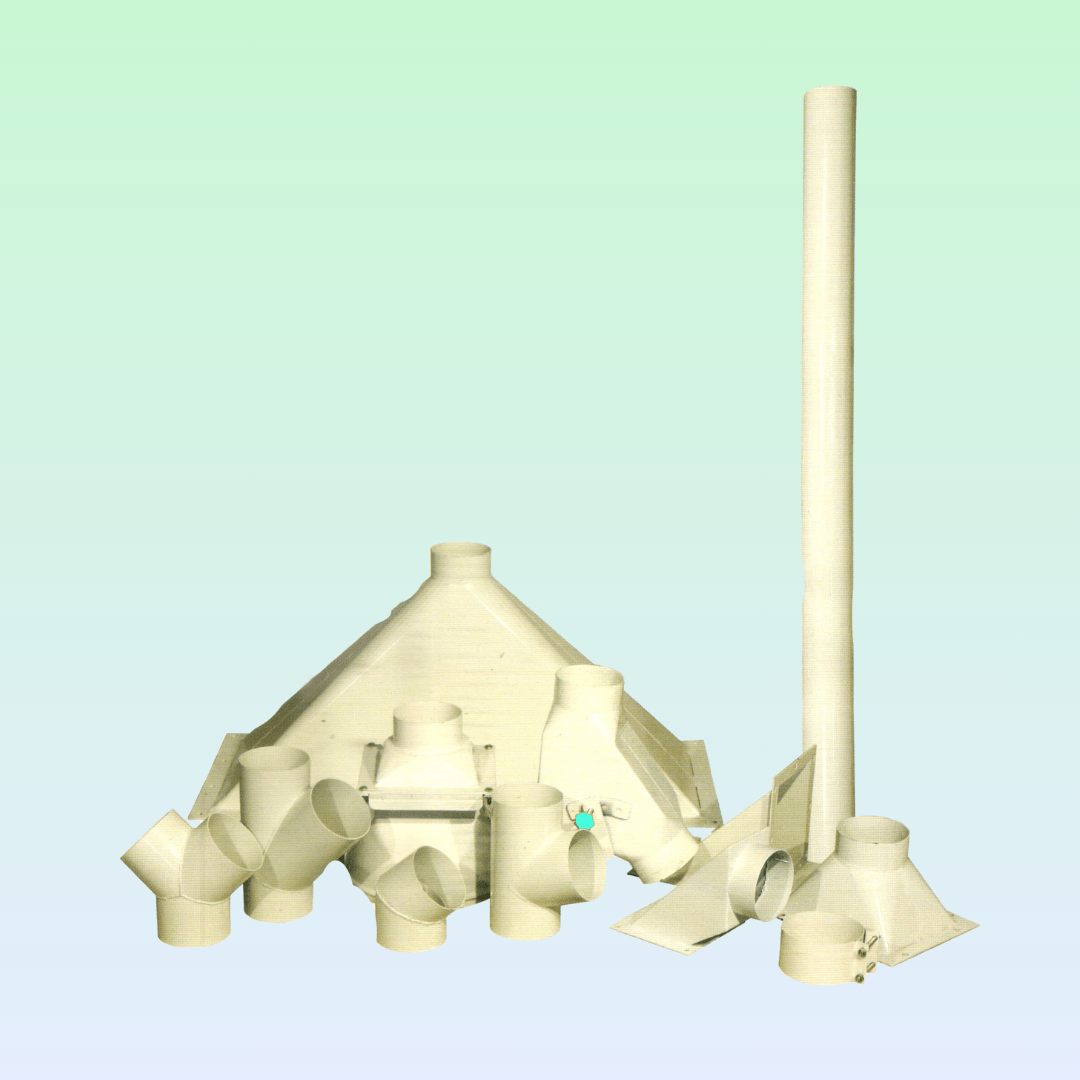

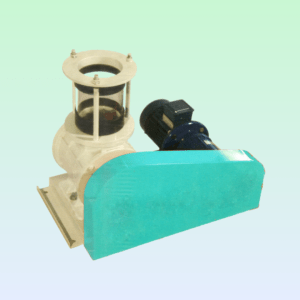

Spouting (MS/SS) refers to a range of metal conduits used to transfer grains, seeds, powders, and other bulk materials between different stages of processing. These spouts are made from Mild Steel (MS) or Stainless Steel (SS), providing strength, durability, and resistance to wear and corrosion. Spouting is an integral part of material handling systems in agricultural and industrial facilities, ensuring the smooth, efficient, and contamination-free flow of materials.

Applications and Uses:

- Grain and Seed Processing: Spouting (MS/SS) is commonly used in grain and seed processing plants to transport materials like wheat, rice, maize, and barley between cleaning, sorting, and milling equipment. The spouts ensure a continuous flow of materials, minimizing spillage and reducing the risk of contamination.

- Pulse and Legume Transport: In pulse processing plants, spouting systems efficiently convey lentils, chickpeas, beans, and other legumes between different processing stages, such as de-stoning, cleaning, grading, and packaging. They help maintain product quality by preventing cross-contamination and ensuring a smooth transition between stages.

- Feed and Flour Mills: Spouting is also vital in feed mills and flour production facilities, where it is used to move raw ingredients like grains and additives to grinding, mixing, and blending stations. This reduces manual handling, improves operational efficiency, and maintains product consistency.

- Storage and Silo Filling: Spouting systems are essential for filling silos and storage bins with grains, seeds, and other bulk materials. They facilitate the controlled flow of materials, preventing blockages and ensuring even distribution within storage units.

- Industrial Applications: Beyond agricultural uses, spouting (MS/SS) is employed in various industrial sectors to transport a wide range of materials, including chemicals, minerals, and plastics, between processing equipment. Their robust construction and versatility make them suitable for many applications.

Key Features:

- Durable Construction: Made from Mild Steel or Stainless Steel, these spouts are designed to withstand continuous use in demanding environments, providing long-term durability and reliability.

- Efficient Material Flow: Smooth interiors and precision-engineered designs ensure minimal friction and resistance, facilitating efficient material flow and reducing blockages.

- Corrosion and Wear Resistance: Stainless steel spouts offer superior resistance to corrosion and wear, making them ideal for handling abrasive or corrosive materials.

- Customizable Designs: Available in various shapes, sizes, and configurations to suit specific processing requirements and facility layouts.

- Easy Installation and Maintenance: Designed for straightforward installation and minimal maintenance, reducing downtime and operational costs.

The Spouting (MS/SS) is a crucial component for any processing facility focused on maintaining efficient, contamination-free material handling. Its robust construction, versatility, and ability to handle a wide range of materials make it an invaluable addition to agricultural and industrial processing lines.

Reviews

There are no reviews yet.