Description

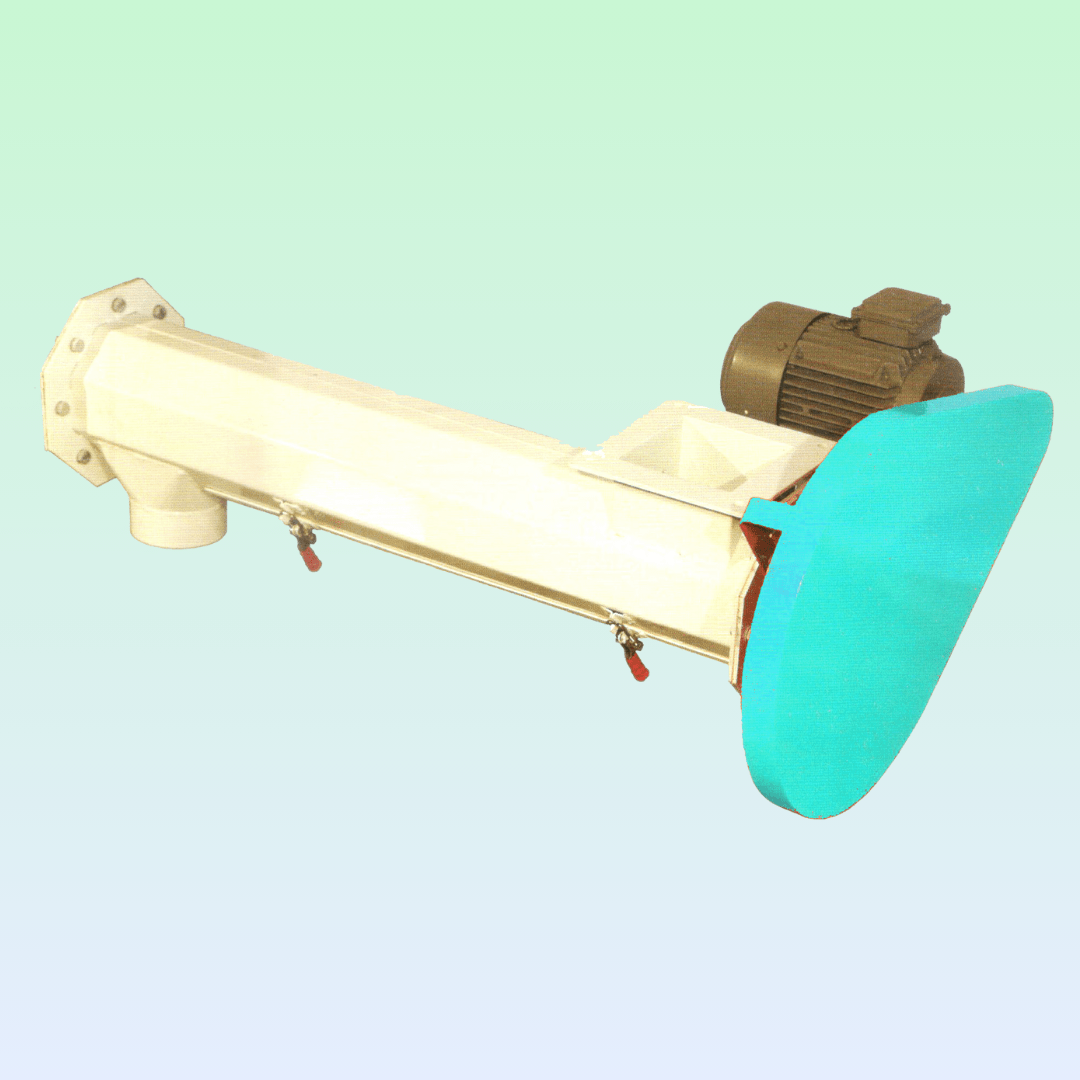

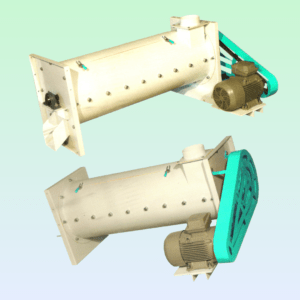

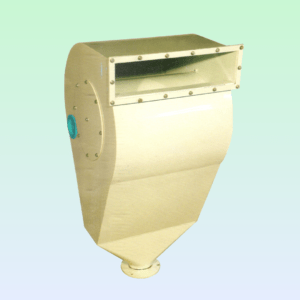

The Screw Feeder is an essential machine designed to provide a precise and controlled flow of grains, seeds, powders, and other bulk materials into processing equipment or production lines. It uses a rotating helical screw within a trough or tube to move materials consistently and accurately, ensuring a smooth feed rate and minimizing waste. Screw feeders are widely used in agricultural processing, food production, and various industrial applications where accurate material dosing is critical for maintaining product quality and optimizing operational efficiency.

Applications and Uses:

- Grain and Seed Feeding: The Screw Feeder is ideal for controlling the flow of grains like wheat, rice, barley, and maize into cleaning, sorting, or milling machines. It ensures that the grains are evenly distributed, reducing clogging and ensuring smooth operation throughout the processing line.

- Pulse and Legume Processing: In pulse processing facilities, the Screw Feeder provides consistent feeding of lentils, chickpeas, beans, and other legumes into dehulling, splitting, or polishing machines. This ensures uniform processing and maintains product quality and consistency.

- Powder Handling in Food Production: The Screw Feeder is commonly used in food production to feed powdered ingredients such as flour, spices, and sugar into mixers, blenders, or packaging machines. Its precise control over the feed rate helps maintain accurate ingredient proportions, enhancing product quality and flavor consistency.

- Feed Mills and Animal Nutrition: In feed mills, the Screw Feeder is used to dose grains, minerals, and supplements accurately into mixing machines, ensuring balanced nutrition in animal feeds. Its consistent operation minimizes ingredient segregation and ensures a uniform blend.

- Industrial Applications: Beyond food and agriculture, screw feeders are utilized in various industries for feeding materials like chemicals, plastics, and minerals into reactors, extruders, or other processing equipment. Their ability to provide a controlled and continuous flow makes them essential for optimizing production processes.

Key Features:

- Precise Material Control: Ensures accurate and consistent feeding of materials, reducing waste and optimizing processing efficiency.

- Versatile Applications: Suitable for a wide range of materials, including grains, seeds, powders, and granules, across various industries.

- Adjustable Feed Rate: Allows operators to control the feed rate to match specific processing requirements, enhancing flexibility and operational efficiency.

- Durable Construction: Made from high-quality materials to withstand continuous operation in demanding environments, ensuring long-term reliability.

- Compact and Space-Saving Design: Designed to fit seamlessly into existing processing lines without taking up excessive space, optimizing production layouts.

The Screw Feeder is a vital component for any processing facility focused on achieving precise material handling and dosing. Its ability to control the flow of materials accurately makes it indispensable for maintaining high standards of quality, consistency, and efficiency in various processing environments.

Reviews

There are no reviews yet.