Description

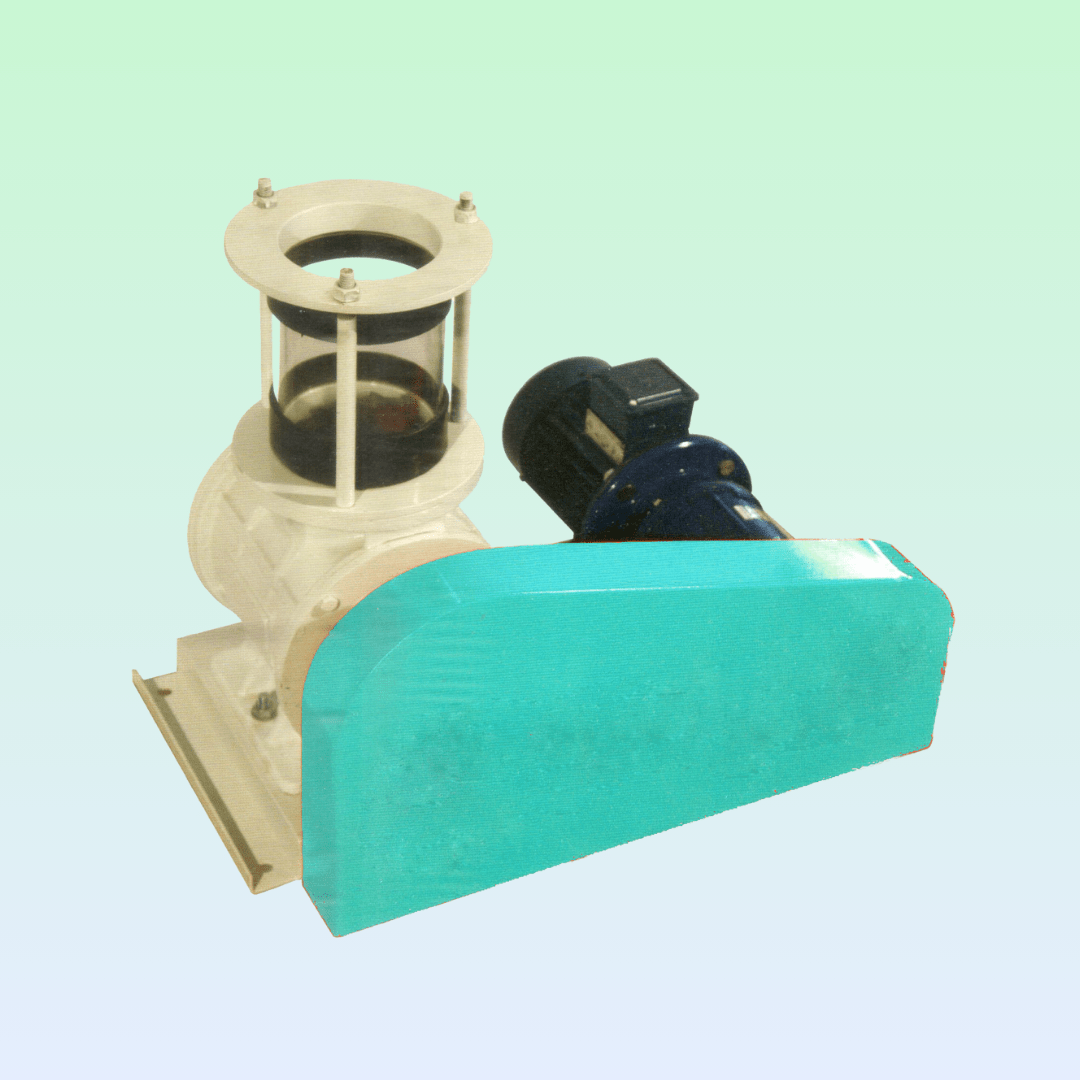

Rotary Air Valve (Air Lock): Precise Material Control and Airflow Management for Efficient Processing

The Rotary Air Valve (Air Lock) is a critical component in agricultural and industrial processing systems, designed to regulate the flow of bulk materials such as grains, seeds, and powders while maintaining an airtight seal. This device is essential in pneumatic conveying systems, where it allows for controlled feeding of materials into pressurized lines without losing air pressure. By ensuring a continuous and consistent flow of materials while preventing air leakage, the Rotary Air Valve enhances the efficiency of dust control, material handling, and various processing operations.

Applications and Uses:

- Pneumatic Conveying Systems: The Rotary Air Valve is widely used in pneumatic conveying systems to feed materials like grains, rice, maize, and pulses into air-driven transport lines. It provides a controlled and consistent flow of materials without disrupting air pressure, ensuring efficient and reliable material transportation.

- Dust Control and Collection: In dust collection systems, the Rotary Air Valve serves as an airlock to maintain an airtight seal while discharging collected dust and debris into storage containers or further processing equipment. This prevents air leakage, enhances dust control, and maintains a clean working environment.

- Feed Mills and Flour Production: Rotary Air Valves are crucial in feed mills and flour processing plants, where they regulate the flow of raw ingredients such as grains, flour, and additives into mixers, grinders, or packaging machines. Their ability to provide precise control over material flow helps maintain product consistency and quality.

- Seed and Grain Processing: In seed cleaning and grain processing operations, Rotary Air Valves are used to control the release of seeds and grains from storage bins into processing lines. They ensure that the material flow is steady and controlled, preventing spillage and ensuring a smooth operation.

- Industrial Applications: Beyond food and agriculture, Rotary Air Valves are employed in various industries to handle materials like chemicals, plastics, and minerals. They are ideal for controlling the flow of fine powders, granules, and other bulk materials in pressurized systems.

Key Features:

- Airtight Sealing: Maintains an airtight seal to prevent air leakage, ensuring optimal performance in pneumatic conveying and dust control systems.

- Precision Flow Control: Provides precise control over material flow, reducing waste and enhancing the efficiency of processing operations.

- Durable Construction: Built with robust materials to withstand continuous operation and handle a variety of materials, from fine powders to coarse grains.

- Low Maintenance: Designed for easy access and maintenance, with minimal moving parts to reduce wear and tear.

- Versatile Applications: Suitable for a wide range of applications, including grain processing, seed cleaning, flour milling, feed production, and various industrial uses.

The Rotary Air Valve (Air Lock) is a versatile and essential tool for any facility focused on efficient material handling and air quality management. Its ability to control material flow while maintaining an airtight seal makes it indispensable for optimizing performance and ensuring product quality in diverse processing environments.

Reviews

There are no reviews yet.