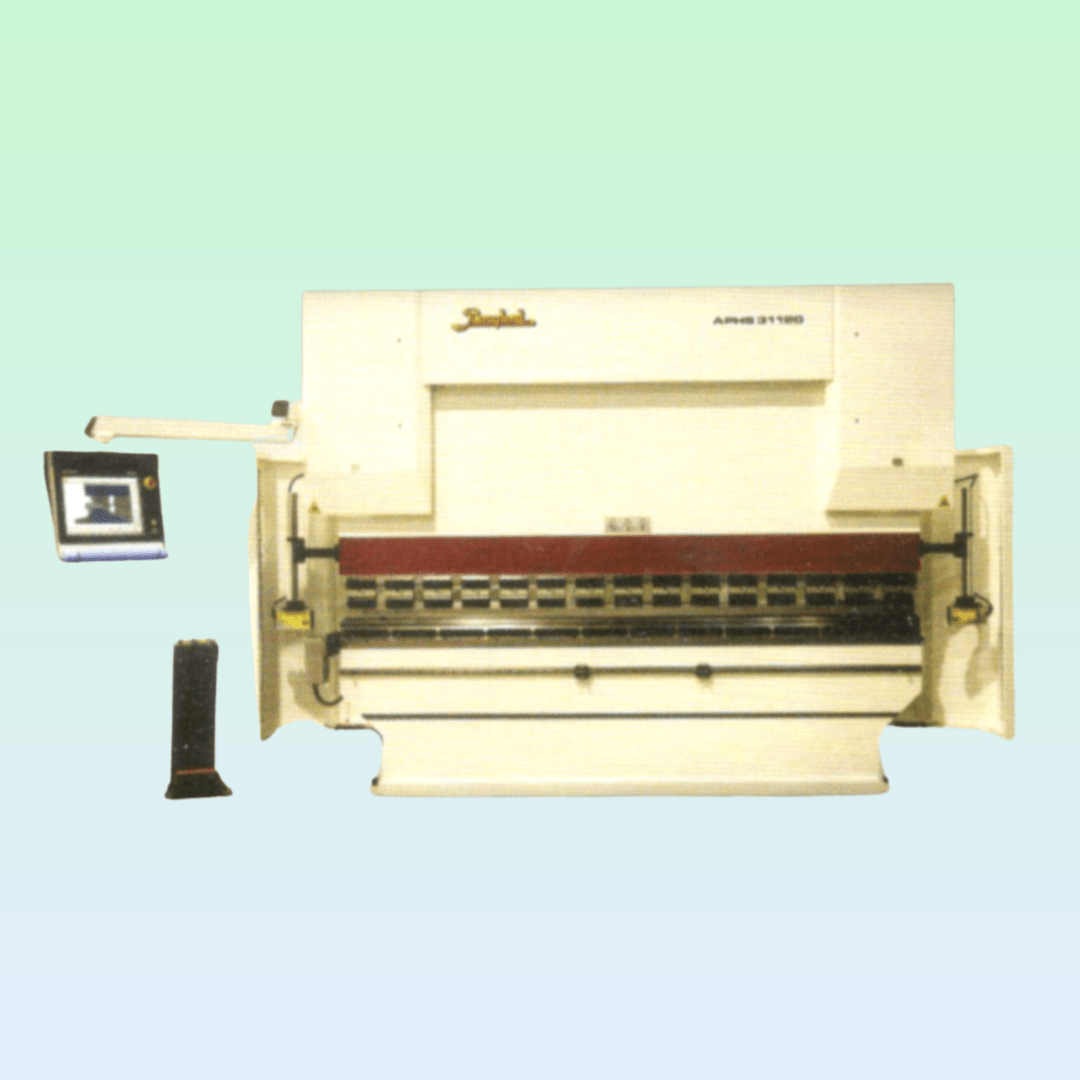

Description

The Hydraulic Press Brake Machine is a powerful and versatile tool designed for bending and shaping sheet metal and plate materials. Using hydraulic pressure to exert force, this machine precisely bends metal to create complex shapes and angles, making it indispensable in manufacturing, automotive, aerospace, and construction industries. The hydraulic press brake is known for its accuracy, reliability, and ability to handle various metals, including steel, aluminum, and stainless steel.

Applications and Uses:

- Sheet Metal Bending: The hydraulic press brake is primarily used for bending sheet metal to create various parts and components. It is ideal for producing panels, enclosures, brackets, and frames used in various industries, ensuring high precision and repeatability.

- Automotive Parts Manufacturing: In the automotive industry, hydraulic press brakes are used to form car body panels, chassis components, and other metal parts. Their ability to produce precise and consistent bends ensures the quality and safety of automotive parts.

- Aerospace Component Fabrication: The aerospace sector relies on hydraulic press brakes for fabricating aircraft parts, including wings, fuselages, and structural components. The machine’s accuracy is critical in meeting the strict tolerances required for aerospace applications.

- Construction and Structural Applications: Hydraulic press brakes are used in the construction industry to bend metal beams, columns, and support structures. They help in shaping materials needed for building frameworks, bridges, and other infrastructure projects.

- Custom Metal Fabrication: This machine is essential for custom metal fabrication shops, allowing for the production of specialized parts and components tailored to specific client requirements. Its flexibility and precision make it suitable for both small-scale custom jobs and large-scale production runs.

Key Features:

- High Precision and Accuracy: Utilizes hydraulic pressure to deliver precise and consistent bending, ensuring uniformity across multiple parts.

- Robust Construction: Built with durable materials to handle heavy-duty bending operations and withstand continuous use in industrial environments.

- Versatile Operation: Capable of bending various metals and alloys, including steel, aluminum, and stainless steel, accommodating different thicknesses and lengths.

- Adjustable Parameters: Equipped with adjustable back gauges, bend angles, and pressure settings to suit different bending tasks and material types.

- Enhanced Safety Features: Includes safety guards, emergency stop functions, and user-friendly controls to ensure operator safety and ease of use.

The Hydraulic Press Brake Machine is a crucial asset for any facility involved in metalworking and fabrication. Its precision, versatility, and reliability make it ideal for producing high-quality metal parts and components, meeting the demands of modern industrial applications.

Reviews

There are no reviews yet.