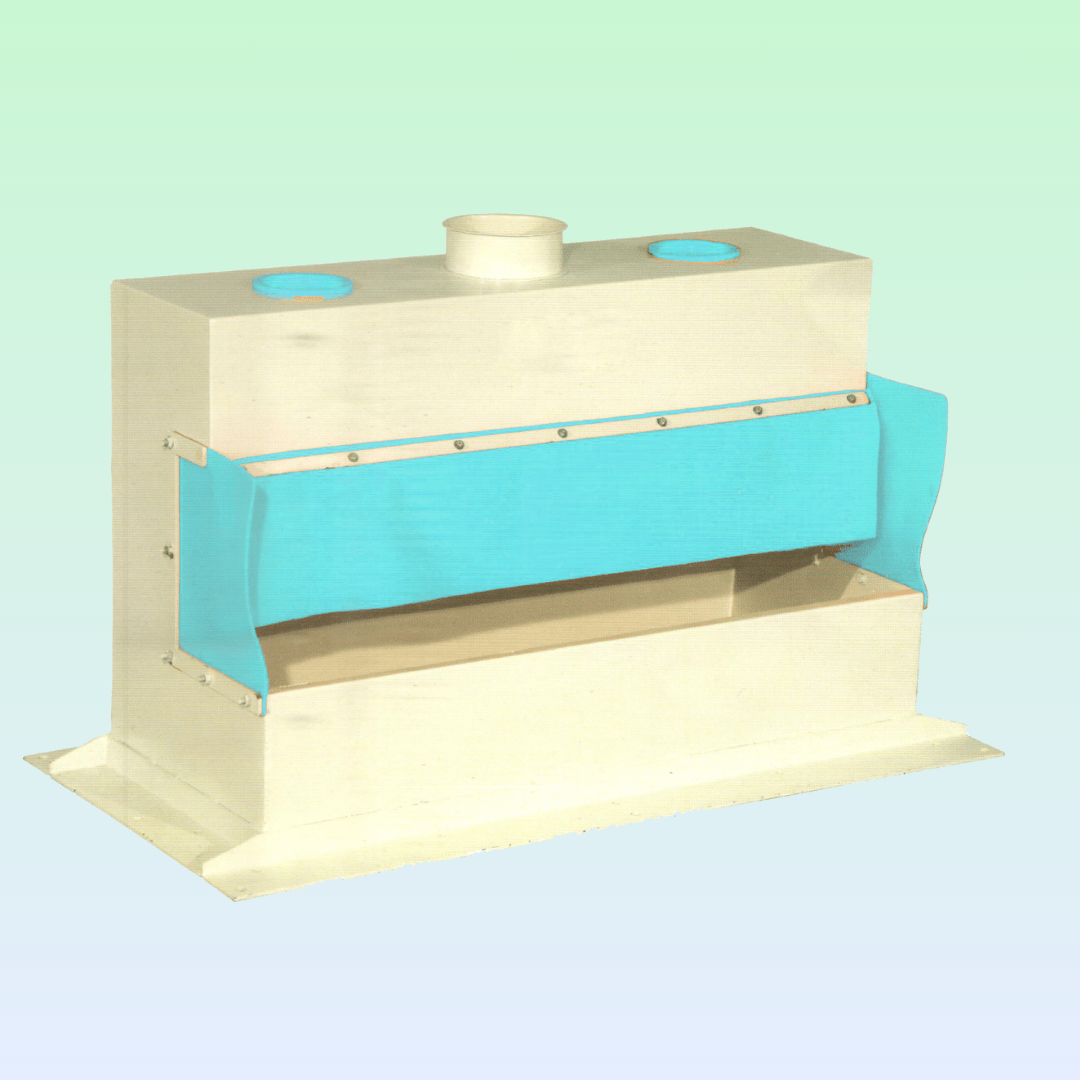

Description

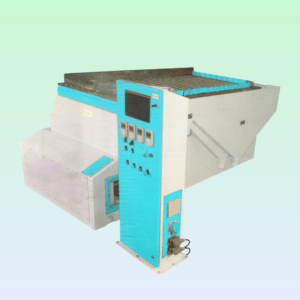

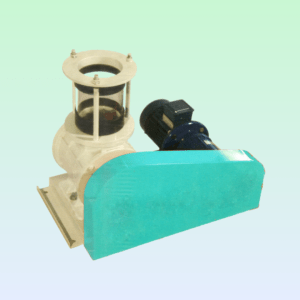

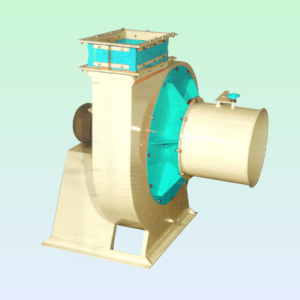

The Air Box is a crucial component in agricultural and industrial processing systems designed to regulate and manage airflow, ensuring efficient dust control and material separation. It is typically used in conjunction with aspiration channels, separators, and other processing equipment to maintain a clean working environment and improve the overall efficiency of grain, seed, and pulse cleaning operations. By controlling the airflow, the Air Box helps to precisely separate lighter impurities such as dust, husk, and chaff from heavier materials, ensuring high-quality output and minimal waste.

Applications and Uses:

- Dust Control in Grain Processing: The Air Box is extensively used in grain processing plants to manage dust and light impurities. By optimizing the airflow, it ensures that dust and other fine particles are effectively separated from grains such as wheat, rice, and maize, improving the cleanliness of the final product and reducing contamination.

- Seed Cleaning Operations: In seed processing, the Air Box plays a vital role in separating seeds from lightweight debris, such as husks, chaff, and broken seed particles. This improves seed purity, quality, and overall germination potential, making it essential for producing high-quality planting seeds.

- Pulse and Legume Processing: The Air Box is used to control airflow in pulse processing plants, aiding in the removal of light impurities from lentils, chickpeas, and beans. This ensures that only clean, high-quality pulses are processed and packaged for market distribution.

- Feed Mills and Flour Production: The Air Box is also an important component in feed mills and flour production facilities, where it helps control dust and maintain product quality by ensuring that only the cleanest raw materials are used in the production process.

- Specialty Crop Processing: In addition to grains and seeds, the Air Box is employed in the processing of specialty crops like spices, coffee beans, and herbs, where it helps to remove dust and other fine particles, maintaining product quality and flavor.

Key Features:

- Precise Airflow Regulation: Designed to optimize airflow in processing systems, ensuring effective separation of light impurities and enhancing overall system performance.

- Enhanced Dust Control: Effectively reduces dust and fine particle contamination, maintaining a cleaner working environment and improving product quality.

- Versatile Integration: Compatible with various processing equipment, including separators, aspiration channels, and dust collectors, making it adaptable to different processing setups.

- Robust Construction: Built with high-quality materials to withstand continuous operation in demanding environments, ensuring long-term reliability.

- User-Friendly Design: Easy to install, operate, and maintain, with adjustable settings for customized airflow management based on specific processing requirements.

The Air Box is an essential tool for processors seeking to improve the efficiency of their cleaning and separation processes. Its ability to regulate airflow precisely and manage dust makes it a valuable addition to any processing line dedicated to maintaining high standards of cleanliness and product quality.

Reviews

There are no reviews yet.